R S T

Waste-To-Energy

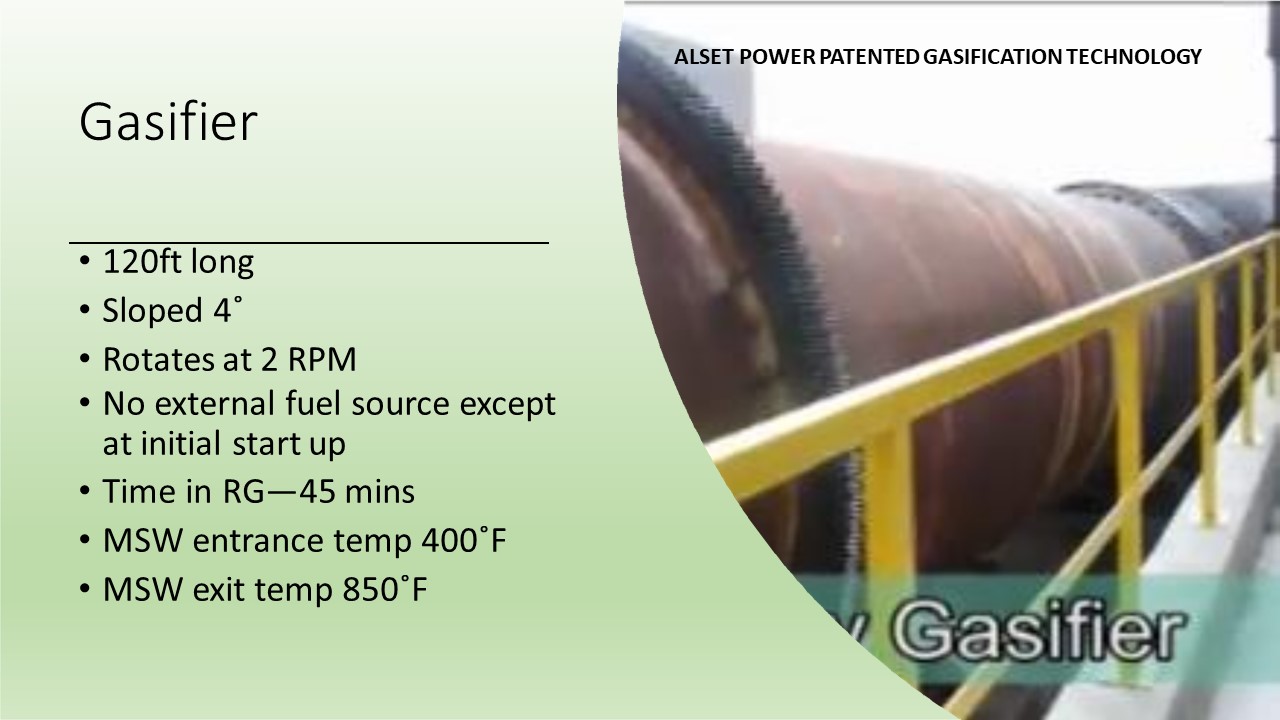

Alset Power Company has incorporated the most efficient waste-to-energy technology into its MSW projects

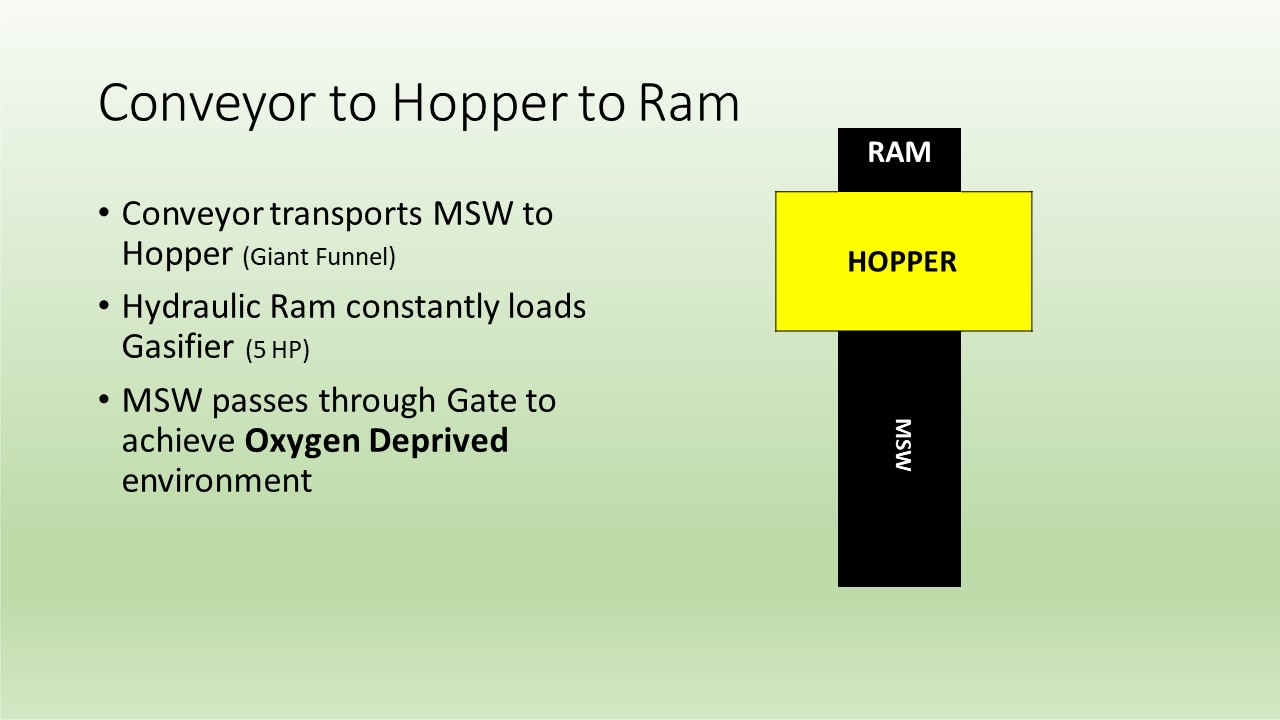

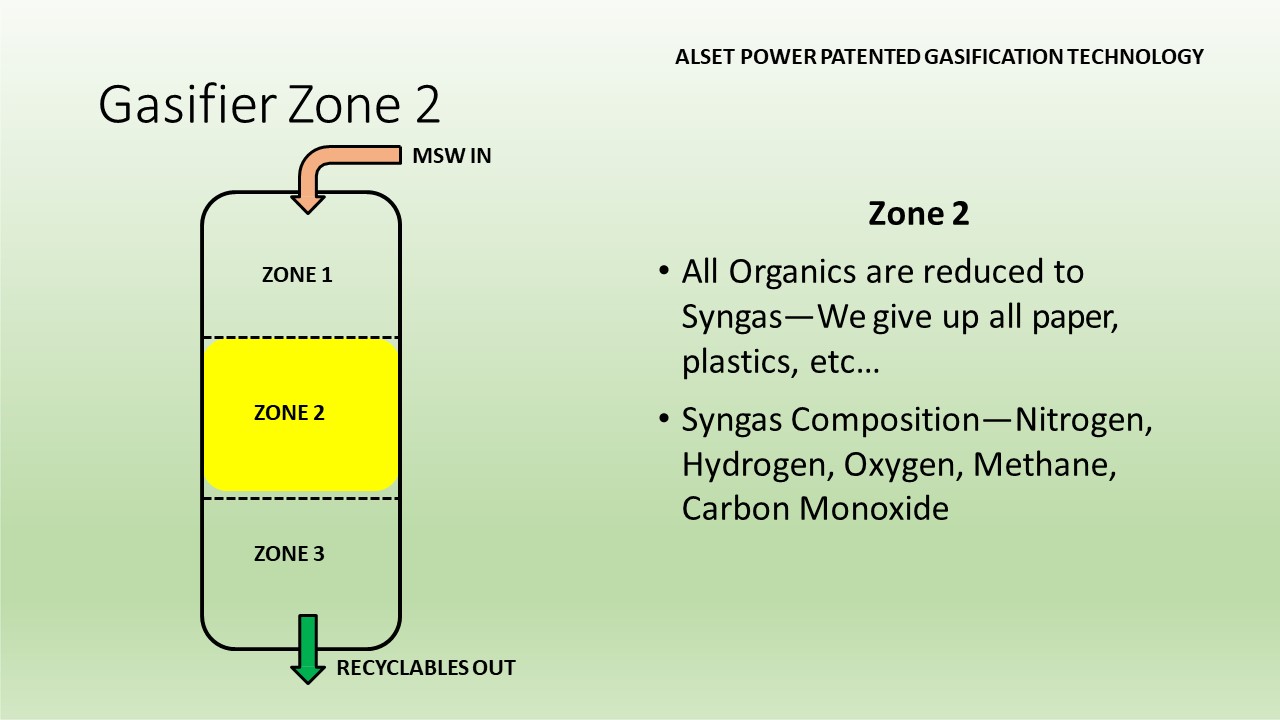

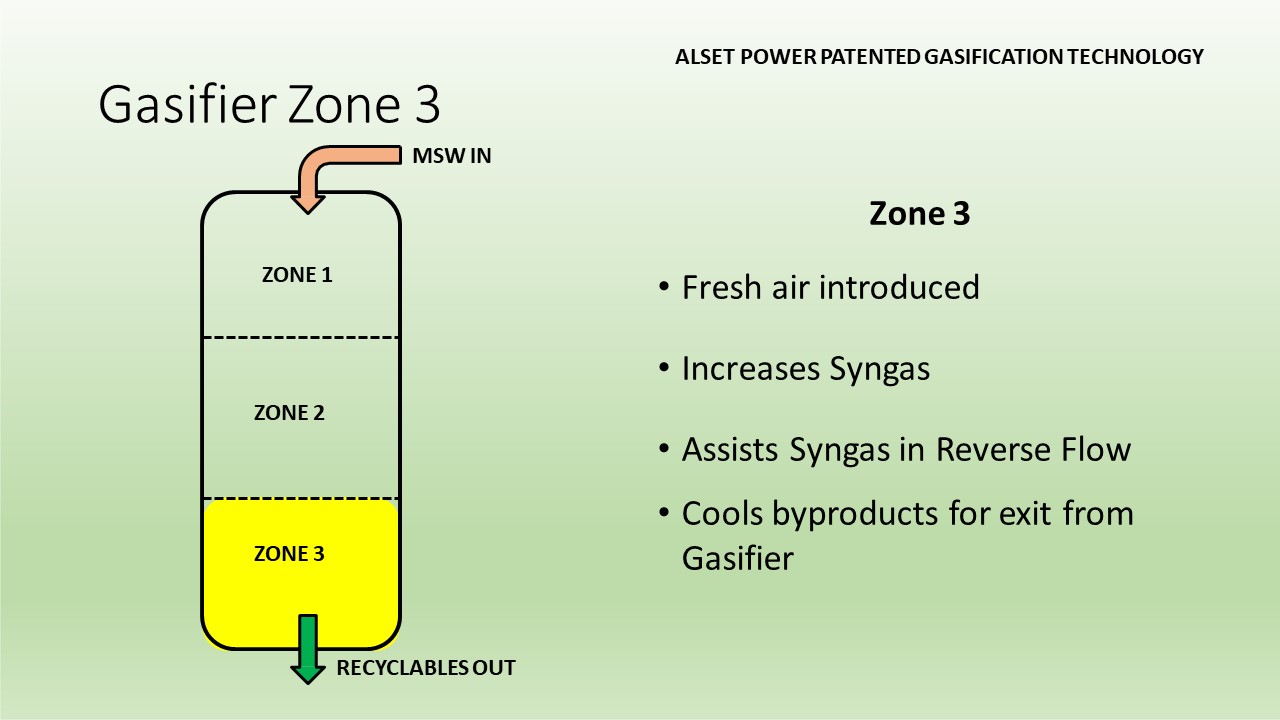

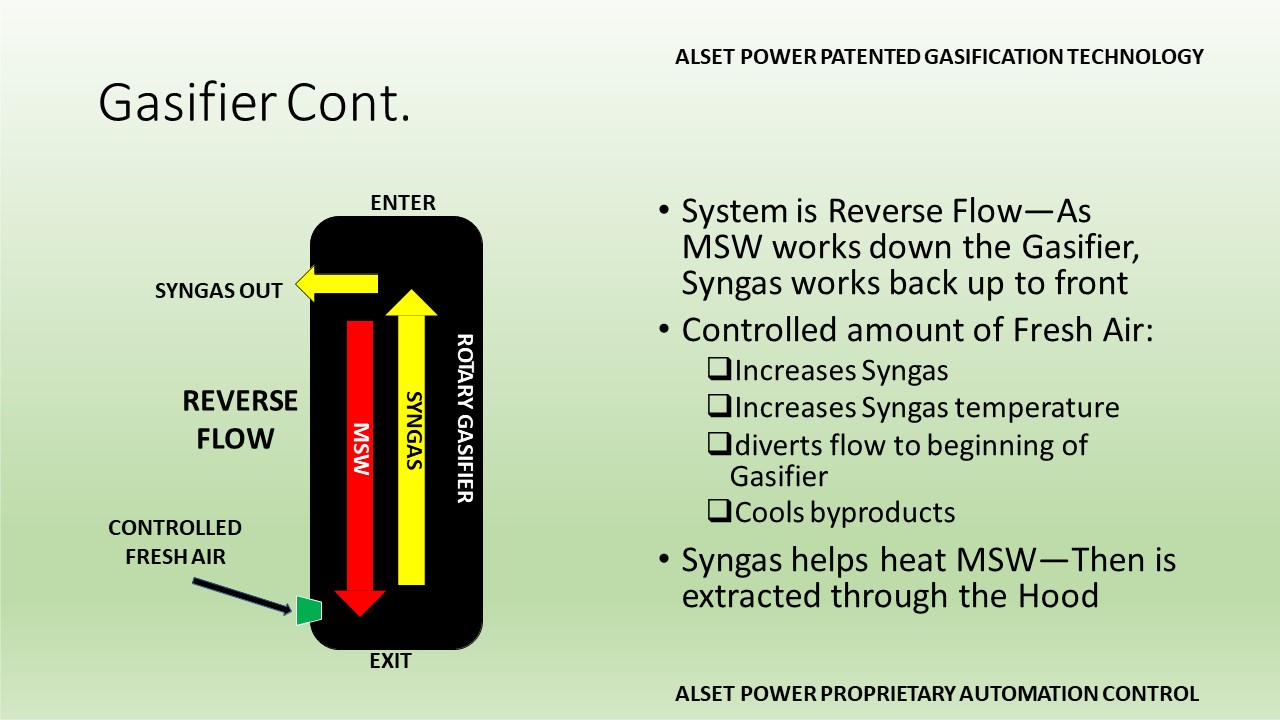

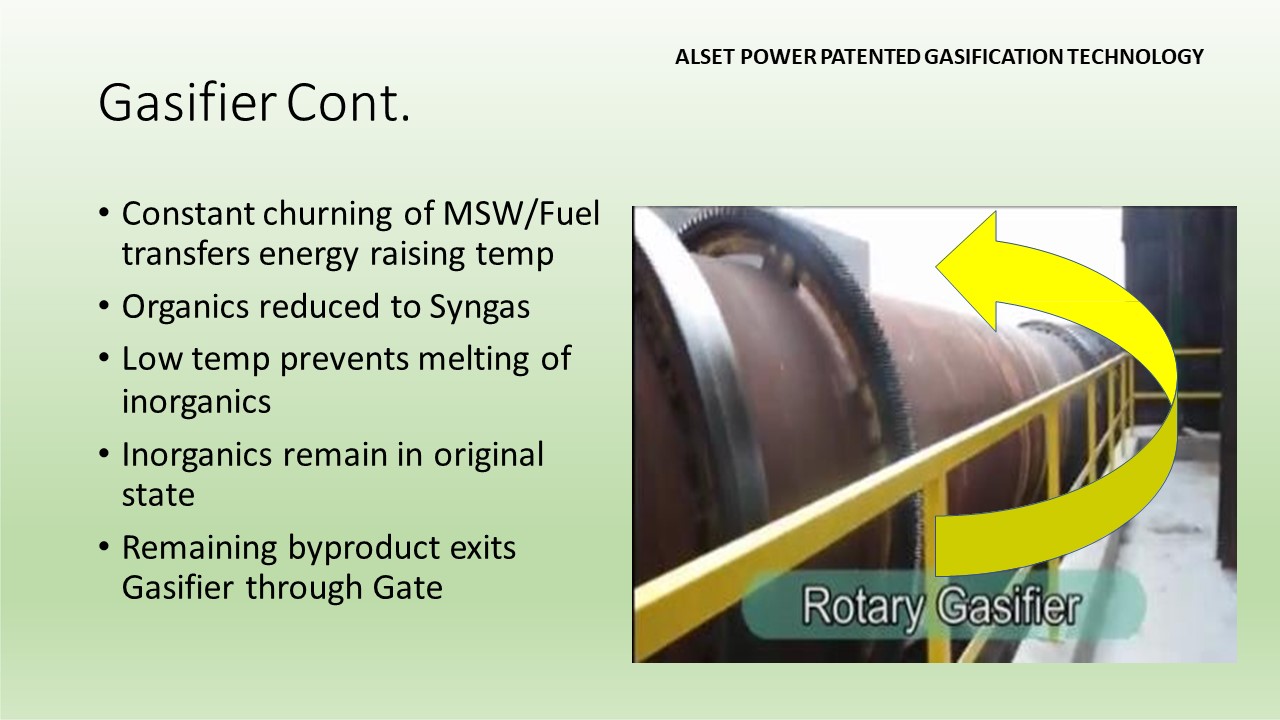

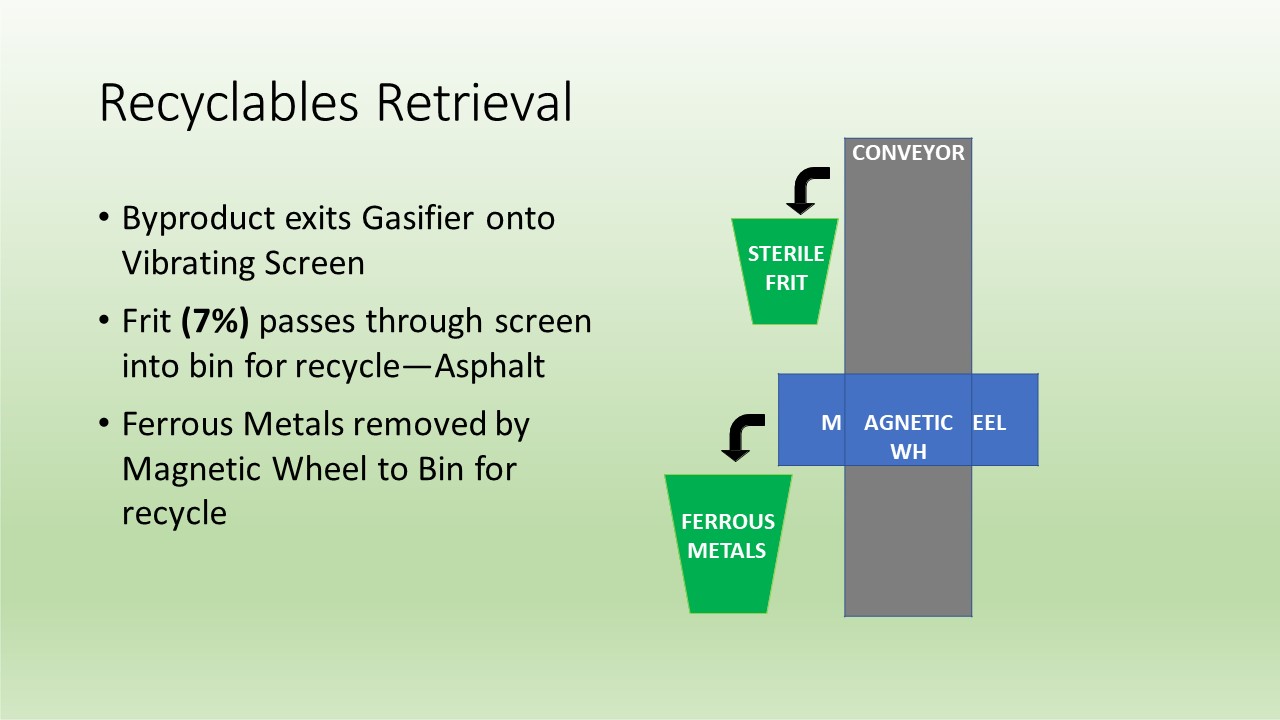

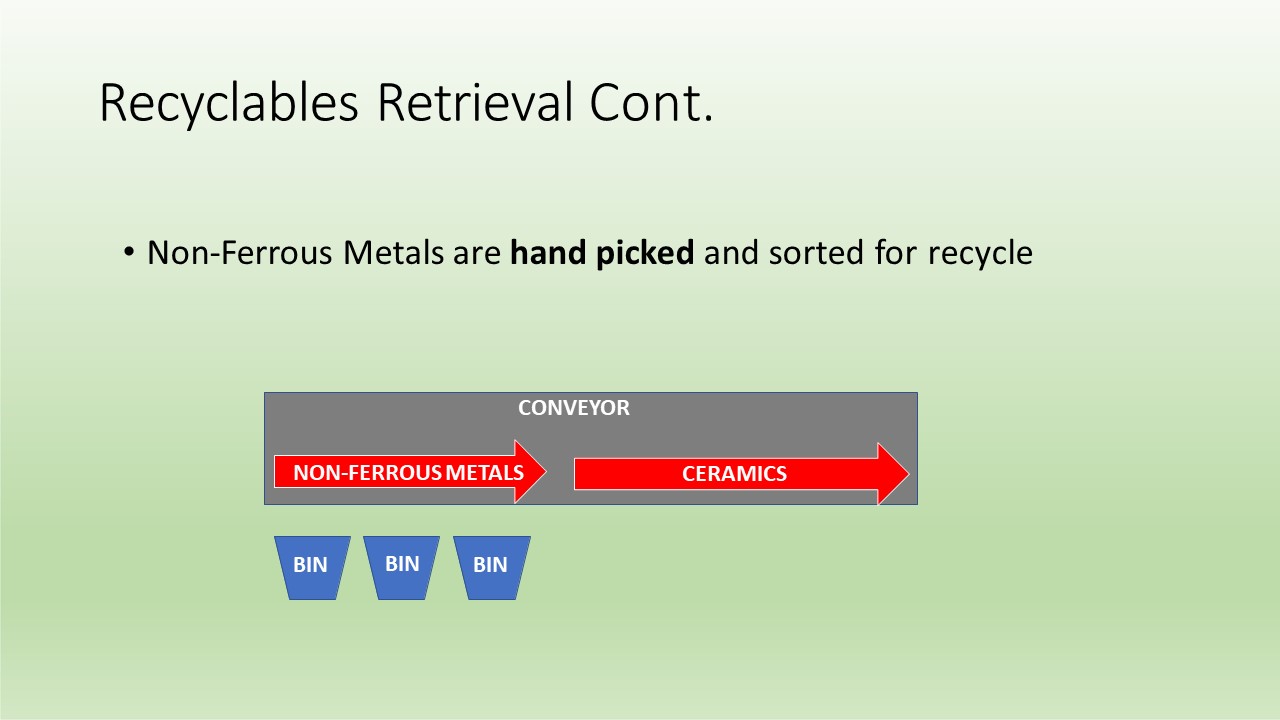

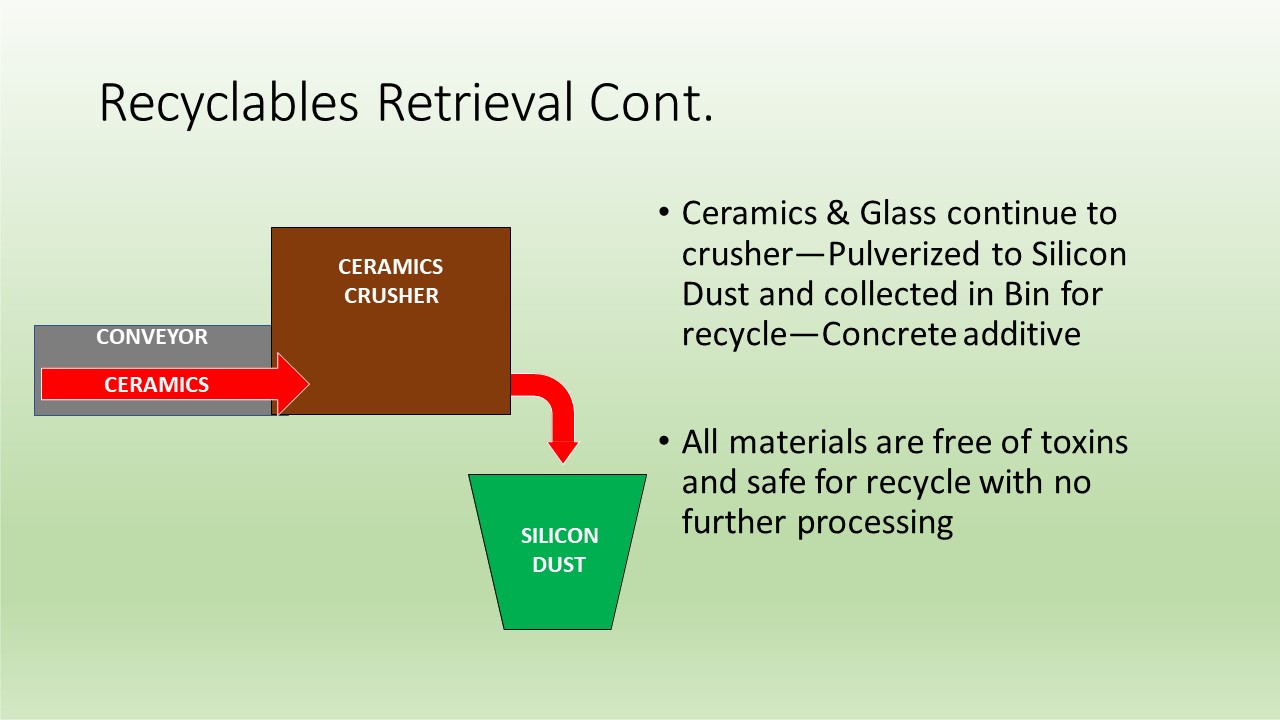

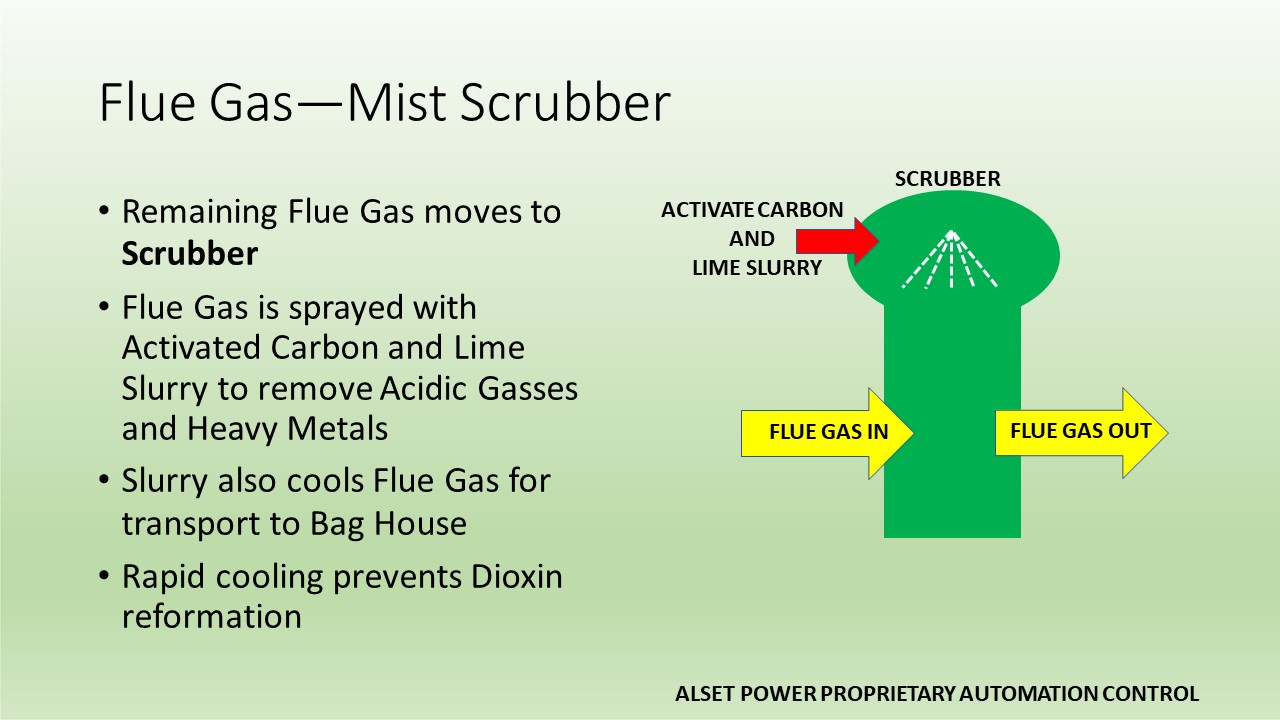

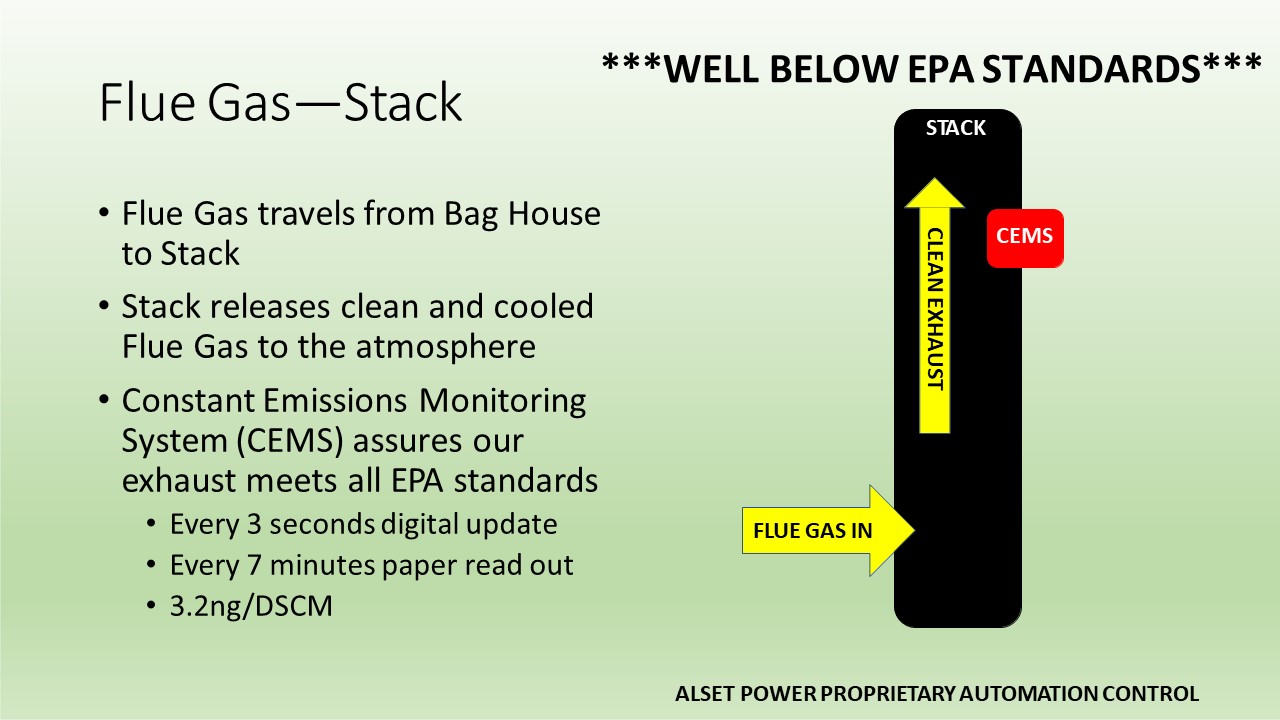

This RST technology processes the waste without any sorting whatsoever. This is a huge labor-saving step that is eliminated in the process. Because this is a gasification process, there is no air pollution and there is no ground water pollution. This new technology has received the highest rating from the EPA for the cleanness associated with the process. The RST process also destroys all plastics and rubber tires, rendering the remaining final substance 100% inert. The remaining results of the process are a combination of ferrous and non-ferrous metals, which are recycled, glass and ash. The glass is crushed and sold for the manufacture of concrete as is the remaining ash. There is nothing remaining to send to the landfill.

Plant Specifics Alset Technology

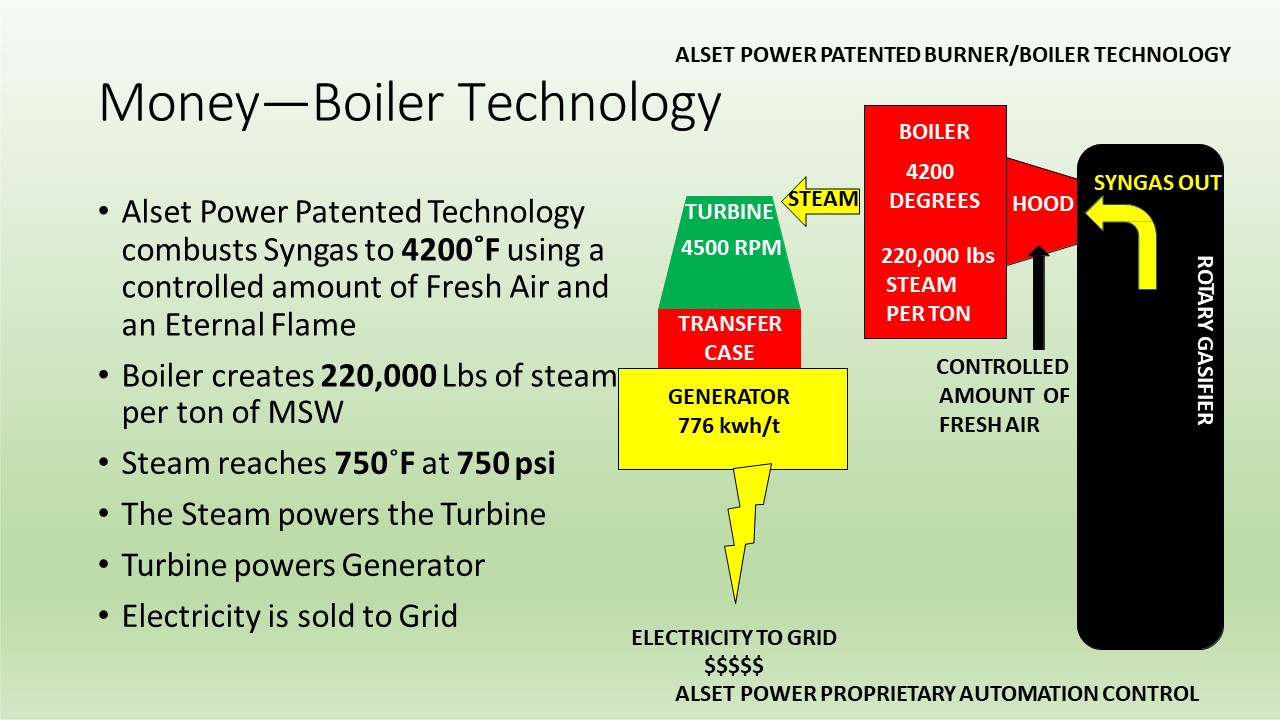

1. Produces 45% more electricity than any other WTE technology with comparable feedstock

2. Feedstock requires no pre-treatment or pre-sorting

3. 100% recyclable byproducts—NO LANDFILL

4. Small foot print—3-5 acres

5. Requires no fuel other than MSW

6. Scalability—Grows with your needs

7. Meets Clients’ needs to handle feedstock

The commercially operating Inez, Kentucky plant is currently being retro-fitted with our new updated, patented technology. The owner has increased the production, energy output and streamlined the size of his RST power plant. The W2E plant can be built on 3-5 acres of land as there is no need for any storage of extra fuel to operate our plant.

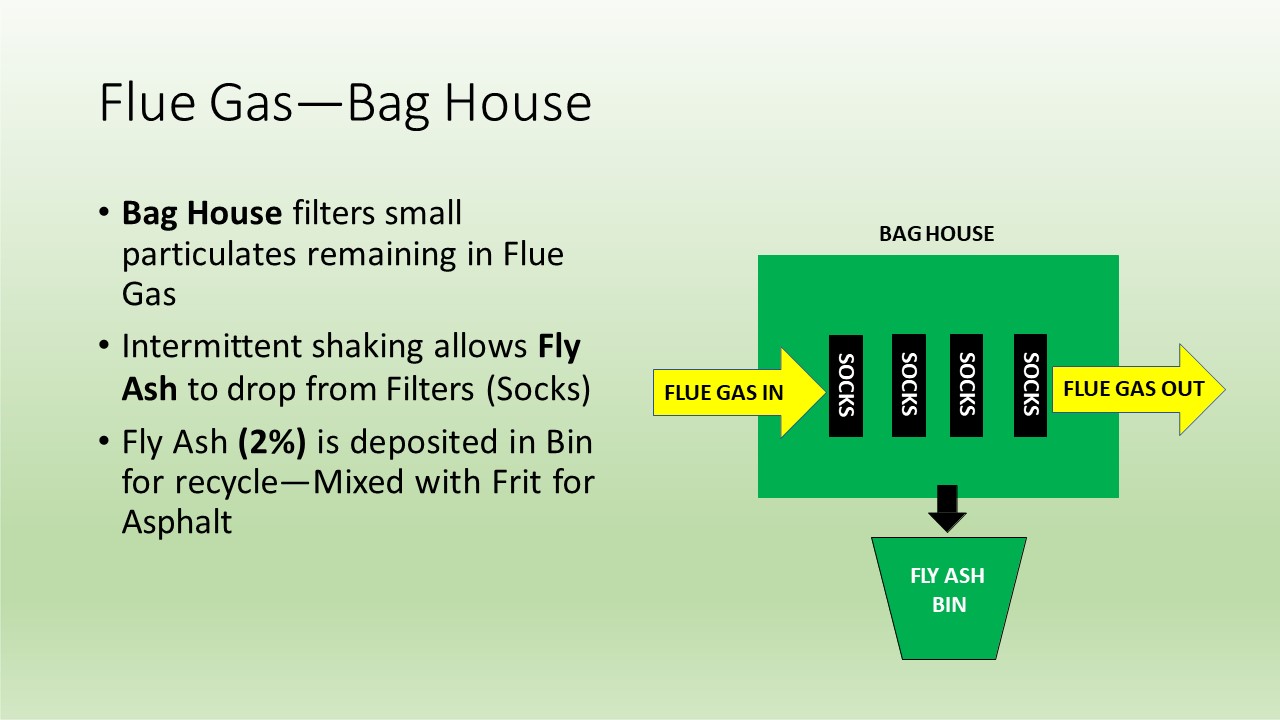

This RST technology allows you to take MSW and reduce it to 100% recyclable products with no need for landfill. Outputs include ready for recycle ferrous and non-ferrous metals, safe reusable mineral frit and fly ash ready for consumption in construction of asphalt, manufacturer ready silicon dust for concrete, and electricity.

Should you need financing to build a plant, we have a finance team ready to consult with you on many ways to finance your needs.

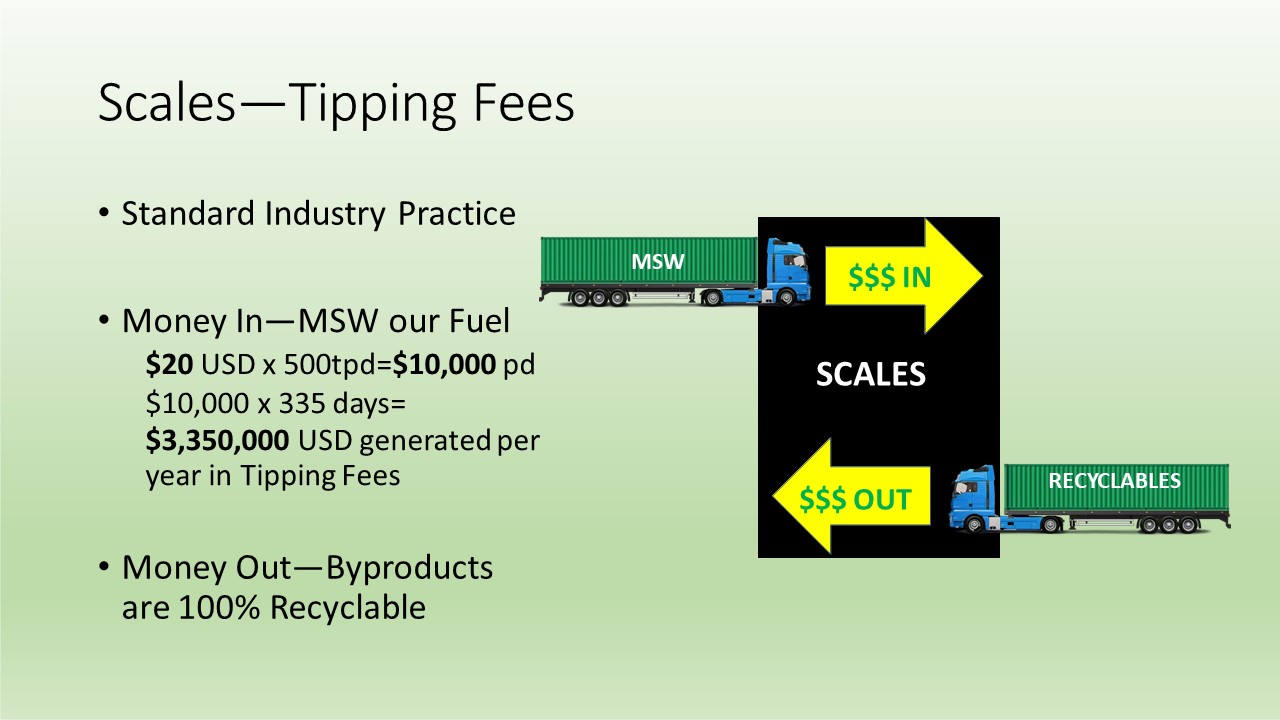

Plant Economics

We must first analyze the MSW produced in your region to give you an accurate estimate on the amount of energy produced by your specific plant.

Based on US MSW we can achieve 776kwh per ton of trash, with less than 25% moisture. Our China partners have lower caloric value and higher moisture content in their waste. But, we will achieve 45% more electric production than all other technologies available with any similar feedstock. Our team can help to raise the heat value of a particular MSW to reach the optimum performance achievable.

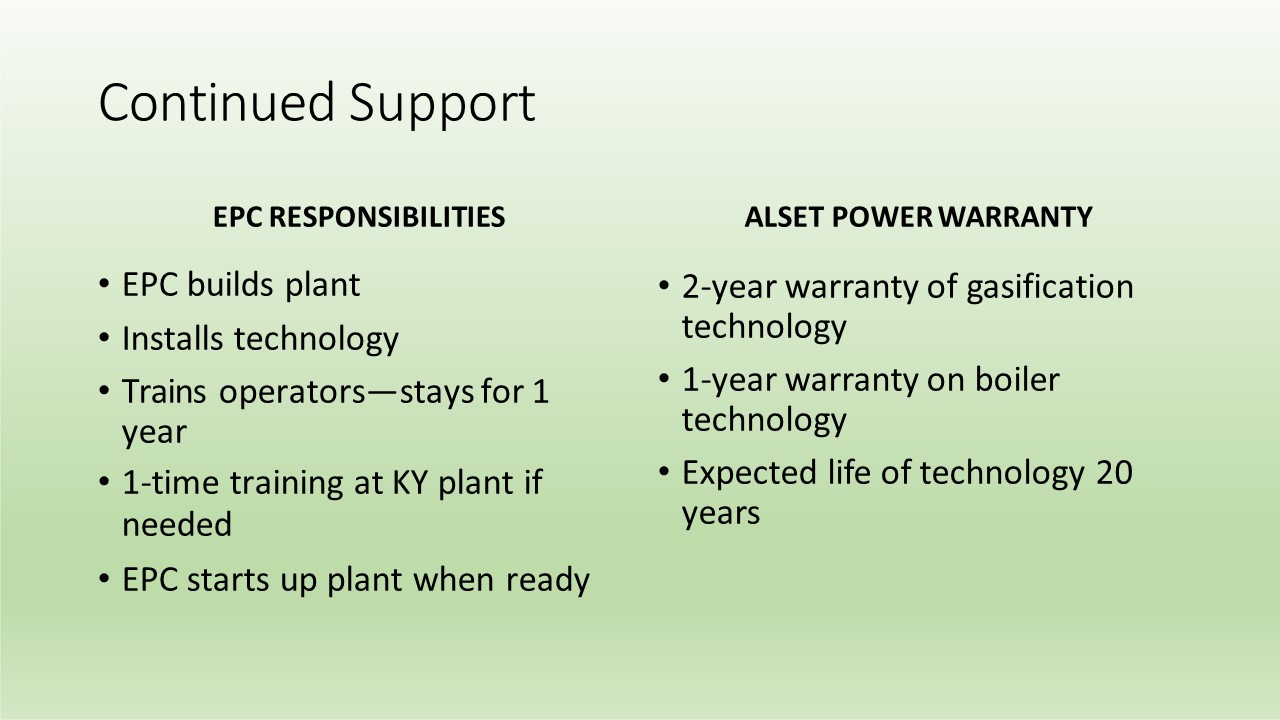

The investment is controlled by Alset Power Company and our EPC, who is typically Siemens. We provide a detailed list of all equipment needed and all specs associated. This allows us to control the costs. Estimates vary. Average estimates are around $60 million per smaller projects, with many predicting much less.

Power Point Presentation